Gear oil pumps play a pivotal role in maintaining the functionality and longevity of various mechanical systems, ranging from automotive engines to industrial machinery. Understanding their significance, types, functioning, and maintenance is essential for optimizing performance and preventing costly breakdowns.

What is a Gear Oil Pump?

A gear oil is a mechanical device designed to transfer lubricating oil within machinery, ensuring proper lubrication of moving parts to minimize friction and wear. These pumps operate by creating a flow of oil through the meshing of gears within a casing.

Importance of Gear Oil Pump in Machinery

The primary function of a gear oil is to deliver lubricating oil to critical components, such as bearings, gears, and shafts, within machinery. By providing adequate lubrication, gear oil pumps reduce friction, heat generation, and wear, thereby extending the lifespan of mechanical systems and enhancing their efficiency.

Types of Gear Oil Pumps

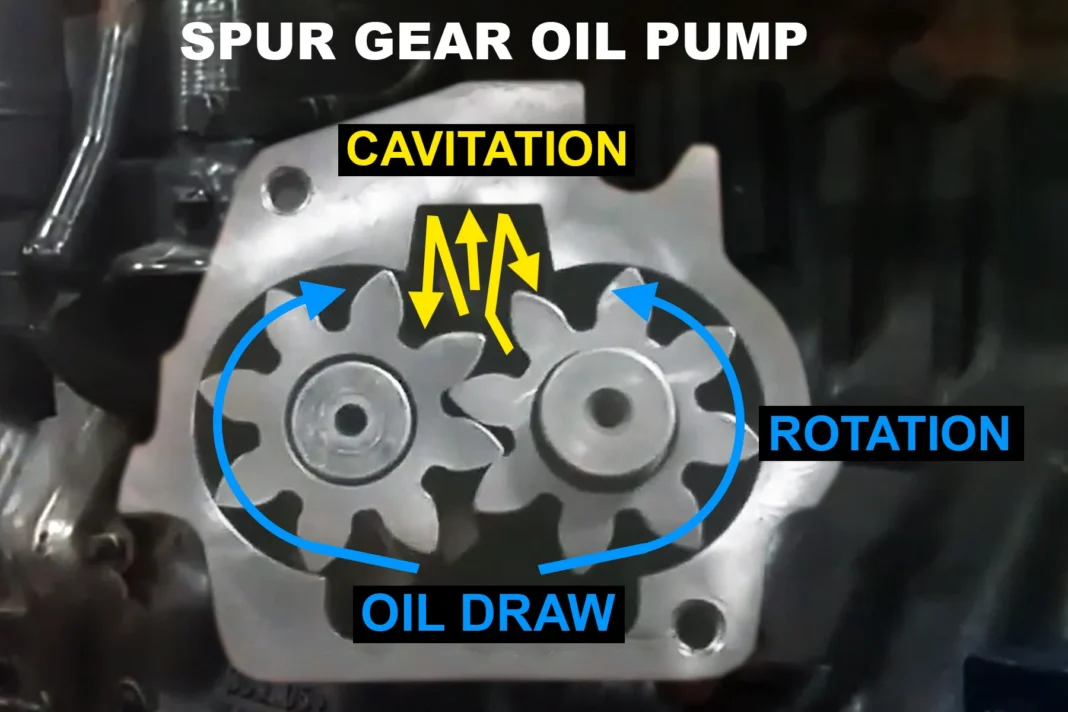

External Gear Pump

External gear pumps consist of two interlocking gears rotating within a casing. As the gears mesh, they create chambers that trap and transport oil from the inlet to the outlet of the pump.

Internal Gear Pump

Internal gear pumps feature an outer rotor with internal teeth and an inner rotor with external teeth. As the rotors rotate, they draw in oil through the inlet and transfer it to the outlet, ensuring a continuous flow.

Gerotor Pump

Gerotor pumps utilize an eccentrically mounted rotor with internal and external gear sets. This design enables efficient oil transfer by creating chambers that vary in volume as the rotor rotates.

Crescent Gear Pump

Crescent gear pumps employ crescent-shaped seals to prevent oil leakage between the gears. These pumps are commonly used in high-pressure applications due to their robust construction and reliable performance.

Functioning of Gear Oil Pump

Gear oil operate on the principle of positive displacement, where a fixed volume of oil is trapped and transported with each revolution of the gears. The pump’s components, including gears, casing, and seals, work in tandem to ensure a consistent flow of lubricating oil to the machinery’s critical parts.

Components of a Gear Oil

Typical components of a gear oil pump include gears, shafts, bearings, casing, inlet/outlet ports, and seals. These components are meticulously engineered to withstand high pressures, temperature fluctuations, and demanding operating conditions.

Lubrication Process

The lubrication process begins with the gear oil pump drawing oil from the reservoir or sump and delivering it to the lubrication points within the machinery. The oil forms a protective film between moving parts, reducing friction and heat generation while enhancing overall performance and reliability.

Applications of Gear Oil Pumps

Gear oil pumps find widespread applications across various industries, including:

Automotive Industry

In automobiles, gear oil pumps ensure proper lubrication of engines, transmissions, and differentials, contributing to smooth operation and extended lifespan.

Industrial Machinery

Gear oil pumps are integral components of industrial machinery, including hydraulic systems, compressors, and gearboxes, where they facilitate efficient lubrication and minimize downtime.

Marine Equipment

In marine applications, gear oil pumps play a crucial role in lubricating propulsion systems, gearboxes, and hydraulic mechanisms, ensuring reliable performance in harsh marine environments.

Factors to Consider When Choosing Gear Oil Pump

When selecting a gear oil pump, several factors must be taken into account, including:

Viscosity Requirements

The viscosity of the lubricating oil must match the operating conditions and temperature range of the machinery to ensure optimal performance and protection against wear.

Operating Pressure

The pump’s capacity to withstand and deliver oil at the required pressure levels is essential for maintaining consistent lubrication under varying loads and operating conditions.

Temperature Conditions

Consideration must be given to the temperature stability of the lubricating oil and the pump’s ability to operate effectively within the specified temperature range.

Maintenance Tips for Gear Oil Pump

Proper maintenance is essential to ensure the longevity and performance of gear oil pumps. Key maintenance practices include:

Regular Inspection

Inspecting the pump for signs of wear, leaks, or damage ensures early detection of potential issues, allowing for timely repairs or replacements.

Proper Lubrication

Using the correct grade and quantity of lubricating oil, as recommended by the manufacturer, helps optimize pump performance and prevent premature failure.

Cleaning and Replacement of Components

Periodically cleaning the pump internals and replacing worn-out seals, bearings, or gears is crucial for maintaining efficiency and preventing costly breakdowns.

Advantages of Gear Oil Pump

Gear oil pumps offer several advantages, including:

Efficient Lubrication

Gear pumps provide a reliable and consistent flow of lubricating oil, ensuring adequate protection against friction and wear in machinery.

Compact Design

The compact size and simple construction of gear oil pumps make them ideal for installation in tight spaces or integrated into existing systems with minimal modifications.

Versatility in Applications

Gear oil pumps can be adapted to a wide range of applications and operating conditions, making them versatile solutions for various industries and machinery types.

Challenges and Solutions

Despite their effectiveness, gear oil pumps may encounter challenges such as overheating, leakage, and wear. Addressing these issues requires:

Overheating Issues

Implementing cooling systems or using lubricating oils with higher thermal stability can help mitigate overheating problems in gear oil pumps.

Leakage Problems

Ensuring proper alignment of pump components and using quality seals and gaskets can prevent oil leakage and contamination of surrounding areas.

Wear and Tear

Regular maintenance, including lubrication and component inspection, is essential for detecting and addressing wear-related issues before they escalate.